Titanium Flange

Titanium flange bụ otu n'ime ihe ndị a na-ejikarị titanium eme ihe.Titanium na titanium alloy flanges na-eji ọtụtụ ihe dị ka ọkpọkọ njikọ maka kemịkalụ na petrochemical akụrụngwa.Ọ nwere njupụta dị ala ma na-arụ ọrụ nke ọma na gburugburu ebe ndị na-emebi emebi.Anyị na-ebu ọkọlọtọ forged titanium flanges ruo 48 "NPS (ASME / ASNI) na mgbali ọnụego si Klas 150 site Class 1200. Ahaziri flanges nwekwara dị site na-enye nkọwa zuru ezu eserese.

| ASME B16.5 | ASME B16.47 | ASME B16.48 |

| AWWA C207 | JIS 2201 | EN 1092-1 |

| MSS-SP-44 | ASME B16.36 |

NPS 1/2" - 48"

ASTM B/SB 381-Ọkara 1,2,3,4,5,7,12

| Nkeji 1, 2, 3, 4 | Azụmahịa Dị Ọcha |

| Nkeji 5 | Ti-6 Al-4V |

| Nkeji 7 | Nke-0.2Pd |

| Nkeji 12 | Ti-0.3Mo-0.8Ni |

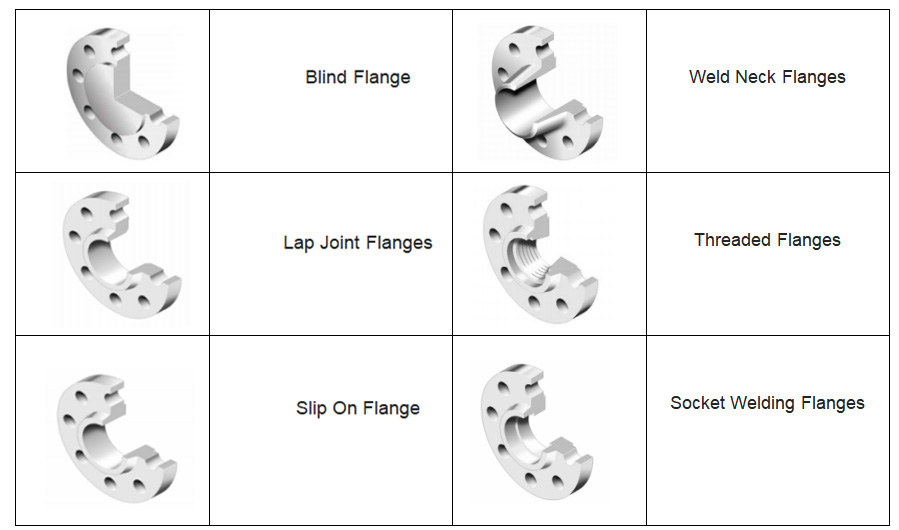

Ngwa Ọmụmaatụ:Mwụpụ, kpuru ìsì, weld becks, orifice, na flanges nkwonkwo ụkwụ

Titanium flange bụ ụdị akụkụ nke titanium metal na-abụghị ígwè ma ọ bụ alloy titanium nke na-ejikọta ọkpọkọ na ọkpọkọ, ma jikọta ya na njedebe ọkpọkọ.Enwere ike nkedo, eri ma ọ bụ welded.Njikọ flange nwere ụzọ flanges, gasket na ọtụtụ bolts na mkpụrụ.A na-etinye gasket ahụ n'etiti ebe mkpuchi nke flanges abụọ ahụ.Mgbe nut na tightened, kpọmkwem nrụgide n'elu nke gasket ga deform mgbe ọ ruru a ụfọdụ uru, na jupụta unevenness na akara n'elu ime ka njikọ siri ike na ntapu-àmà.Ọkwa akara ya: TA0, TA1, TA2, TA3, TA9, TA10, TC4 na ndị ọzọ.

Ọrụ nke flange ọ bụla nke ihe dị iche iche dị iche iche.Titanium flanges nwere ọmarịcha nguzogide corrosion n'ọtụtụ mgbasa ozi.Acid na alkali eguzogide, ogologo ọrụ ndụ, ala njupụta, elu ike, akụrụngwa arọ, ezigbo elu, dịghị unyi, na ukwuu belatara ọnụ ọgụgụ unyi.A na-ejikarị mmanụ ala, ụlọ ọrụ kemịkalụ, ike eletriki, metallurgy, eriri kemịkalụ, nri, ọgwụ, chlor-alkali, mmepụta nnu na-adịghị mma, ụlọ ọrụ kemịkalụ dị mma, injinịa ndu, mmiri mmiri mmiri, injin mmiri na ụlọ ọrụ ndị ọzọ.

Mwụpụ, kpuru ìsì, weld becks, orifice, na flanges nkwonkwo ụkwụ

Titanium flange bụ ụdị akụkụ nke titanium metal na-abụghị ígwè ma ọ bụ alloy titanium nke na-ejikọta ọkpọkọ na ọkpọkọ, ma jikọta ya na njedebe ọkpọkọ.Enwere ike nkedo, eri ma ọ bụ welded.Njikọ flange nwere ụzọ flanges, gasket na ọtụtụ bolts na mkpụrụ.A na-etinye gasket ahụ n'etiti ebe mkpuchi nke flanges abụọ ahụ.Mgbe nut na tightened, kpọmkwem nrụgide n'elu nke gasket ga deform mgbe ọ ruru a ụfọdụ uru, na jupụta unevenness na akara n'elu ime ka njikọ siri ike na ntapu-àmà.Ọkwa akara ya: TA0, TA1, TA2, TA3, TA9, TA10, TC4 na ndị ọzọ.

Ọrụ nke flange ọ bụla nke ihe dị iche iche dị iche iche.Titanium flanges nwere ọmarịcha nguzogide corrosion n'ọtụtụ mgbasa ozi.Acid na alkali eguzogide, ogologo ọrụ ndụ, ala njupụta, elu ike, akụrụngwa arọ, ezigbo elu, dịghị unyi, na ukwuu belatara ọnụ ọgụgụ unyi.A na-ejikarị mmanụ ala, ụlọ ọrụ kemịkalụ, ike eletriki, metallurgy, eriri kemịkalụ, nri, ọgwụ, chlor-alkali, mmepụta nnu na-adịghị mma, ụlọ ọrụ kemịkalụ dị mma, injinịa ndu, mmiri mmiri mmiri, injin mmiri na ụlọ ọrụ ndị ọzọ.